The Steel Arrived But Some Changes Are Necessary

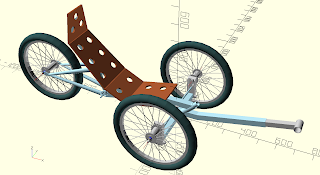

The main frame is cut and ready to be welded, if Melbourne will only give me some decent freakin' weather to get outside with power tools. The crossmember needed a rethink. It's all well and good to make a sensible "engineering" decision (I'm a sound engineer by trade, which isn't a field of actual engineering) and use 35x1.6 SHS for all the main parts, but the decision then leads to using 50x5 SHS for making the lean steering wheel tilt brackets and slightly less than 600g of steel for each. Making the same brackets out of 40x3 reduces the weight to nearer 200g each, but requires the crossmember to be made from 30x1.6, also lighter but for no appreciable loss of strength. For my next trick, I might build a version of it out of 31.8x16x1.6 EHS for AeroAdvantage™. Meanwhile, as an exercise in learning FreeCAD, the design is being refined for a later version. A friend is considering an eTrike as a mobility aid and, if mine works, I'll probably start assem